Optimized CAD Performance in Mechanical and PlantEngineering

The innovative software solution “3D Evolution Simplifier” simplifies the handling of large CAD data models

The "3D_Evolution Simplifier" of the developed by German-French software manufacturer CoreTechnologie, is a software for fast and fully automatic simplification of CAD data. The tool is also a converter that handles the reading and writing of all popular formats such as Catia V5 and V6, NX, Solidworks, Creo, Inventor, Step, IGES, JT, XT, FBX, DWG and DGN. In addition to conversion and simplification, the models can be checked and optimized in terms of quality.

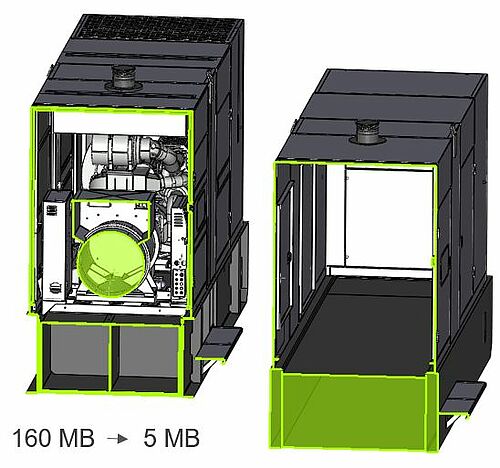

Envelope Geometry improves CAD Performance

In plant engineering, the handling of large 3D CAD models is an important topic. With the increasing level of detail and size of CAD models, the number of entities to be displayed is, in most cases, beyond the capabilities of today's CAD workstations. Automated simplification and data reduction is essential for the control of large volumes of data to create layouts or VR models in the field. The fast and fully automated generation of envelope geometries is a viable solution to smoothly work with large amounts of data, especially in plant construction.

Preparation of Customer or Supplier Data

The Simplifier simplifies and converts supplier data. The removal of internal geometry for the calculation of envelope geometries can be achieved within seconds by pressing a button. For efficient reduction of file size, solids are produced fully automatically without any inner workings. The "Healing" technology ensures the automatic analysis and repair of the 3D models. The automatic correction functions improve data quality to optimize data exchange, especially for imported data.

The result of the simplifier process and quality optimization is the significantly higher performance in the CAD system and in all downstream processes. Particularly suitable is the method for Digital Mock Ups. In addition, problems in the drawing derivation are eliminated by the significantly reduced amount of data and the high quality of the data.

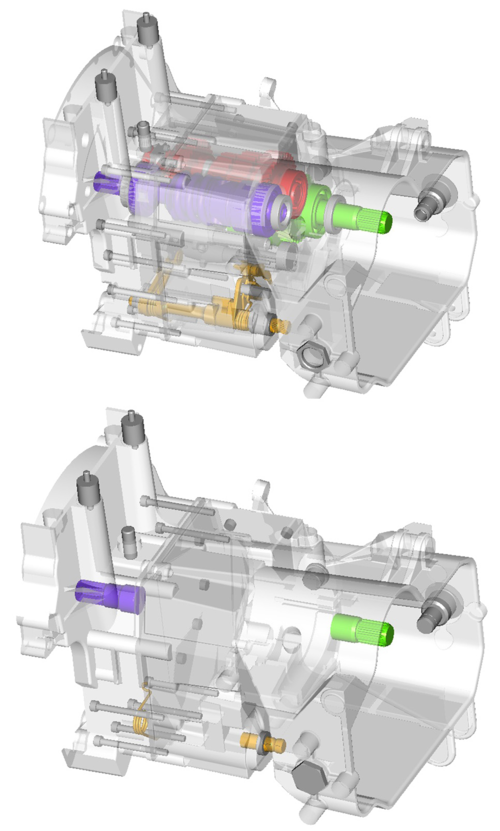

Automated Product Release with Know-how Protection

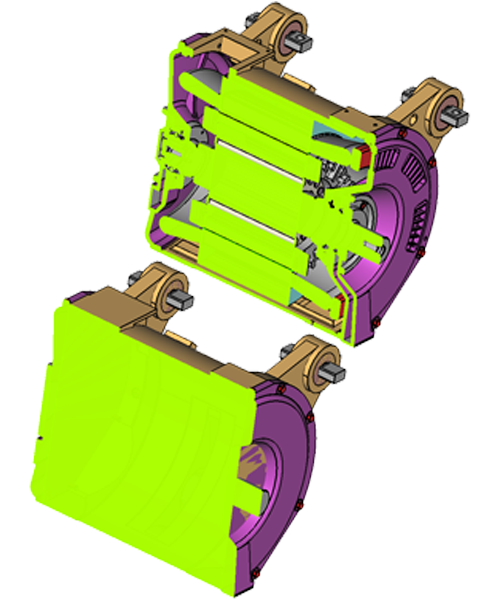

The simplification module is automated in batch mode and can be performed for any number of files and directories. Attributes in the CAD data, colors and names of the components allow precise control of the simplification process. Thus, certain components are specifically excluded from the simplification, completely removed or replaced by highly simplified approximate envelope contours.

The envelope contours provide, in addition to the ultimate protection of know-how, the replacement of the original geometry for an additional reduction in file size. Sheet metal parts can be replaced, for example, by boxes, threads or gears cylinders or more complex geometries with cooling fins by polyhedra. In addition, Enterprise Datamanager offers various automation options. Web-based client / server solutions, multiprocessor operation, command-line operation and the optional directory scanner provide seamless integration into existing PLM environments as needed. The directory scanner monitors defined folders and processes the data stored in them.

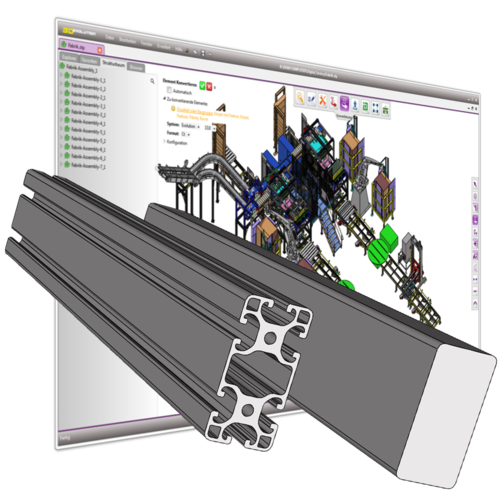

Another option for integration into existing PLM systems is the command line. The integration enables automation for the provision of product data, for example for catalog systems such as Docware or Engineer-to-Order systems such as Siemens PLM Rulestream.

Preparation of Customer or Supplier Data

The Simplifier simplifies and converts supplier data. The removal of internal geometry for the calculation of envelope geometries can be achieved within seconds by pressing a button. For efficient reduction of file size, solids are produced fully automatically without any inner workings. The "Healing" technology ensures the automatic analysis and repair of the 3D models. The automatic correction functions improve data quality to optimize data exchange, especially for imported data.

The result of the simplifier process and quality optimization is the significantly higher performance in the CAD system and in all downstream processes. Particularly suitable is the method for Digital Mock Ups. In addition, problems in the drawing derivation are eliminated by the significantly reduced amount of data and the high quality of the data.

Preparation of CAD Data for VR / AR

When processing CAD data for visualization in virtual or augmented reality, the 3D_Evolution Simplifier is used to drastically reduce the number of polygons without quality disadvantages, ie by 90 percent or more, in typical models from the mechanical and plant engineering sector. The process is based on removing the internal geometry and drilling based on optimized B-REPsolids. After reading the original CAD geometry, the simplification of the exact B-REPdata takes place. Subsequently, the conversion to formats such as obj and fbx with definition of the polygon size as well as the reduction of the tessellation by up to 98 per cent is accomplished. Since Simplifier simplifies simplified B-REP geometry with topology, no holes or unwanted geometry deformations occur.